What is RFID?

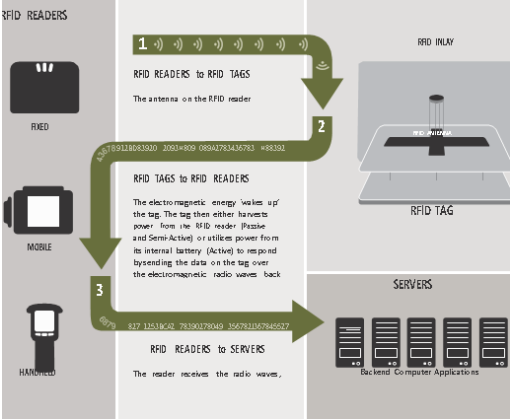

- Radio Frequency Identification (RFID) uses radio waves to

read and capture information stored on a tag attached to an object. - A tag can be read from up to several feet away and does not need to

be within direct line-of-sight of the reader to be tracked. - The industry uses RFID by incorporating a microchip into a

product’s hang tickets or labels. This microchip is then matched to

the individual product. - Each microchip has a unique serial number which allows the retailer

to track, count, and manage the stock at the specific item level. - By using an RFID handheld terminal (HHT) a shop floor associate can

quickly and easily count large numbers of items on a monthly,

weekly or daily basis. - The HHT has a reader on the front which is passed near the items to

be counted and each ticket is then read by the HHT. - By using this technology it is possible to count 100’s of items per

second. This method of stock counting leads to improved stock file

accuracy as each product has a unique id. - Improved stock file accuracy leads to improved availability and

replenishment which in turn leads To higher productivity as

improved Omni Channel offerings with many other advantages. - The Mobile device sends a request via direct connection to the RFID device

to do the inventory of the items at the store level. - RFID device after getting the request from the Mobile device sends a

command to the tags, which are attached to the items to respond and gets

all the information needed to do the inventory. - Each tag identifies itself with a unique number. The tags send information

back to the RFID device via scattered UHF waves. - RFID Device after collecting all the information from the Tags sends the

information in the form of raw data to the Mobile device via direct connection. - Mobile device after collecting all the data from the RFID device, converts the

data to be displayed on the screen so that it is understandable for the

human user and it also transmits the information to the Cloud Server via Wi-Fi or LTE connection, where all the information is collected, and reports are

generated for the customer at the Dashboard.

Will RFID replace the barcode?

RFID could eventually replace bar codes in some applications where bulk counting is routinely performed.

The differences between the two data capture technologies include:

- Line of sight — a bar code scanner and bar code must be visible to each other to enable a successful scan, where RFID tags need only to be within a range to be read.

- Simultaneous tag capture — Bar codes are captured one at a time, whereas RFID tags can be captured in bulk.

- Simultaneous tag capture — Bar codes are captured one at a time, whereas RFID tags can be captured in bulk.

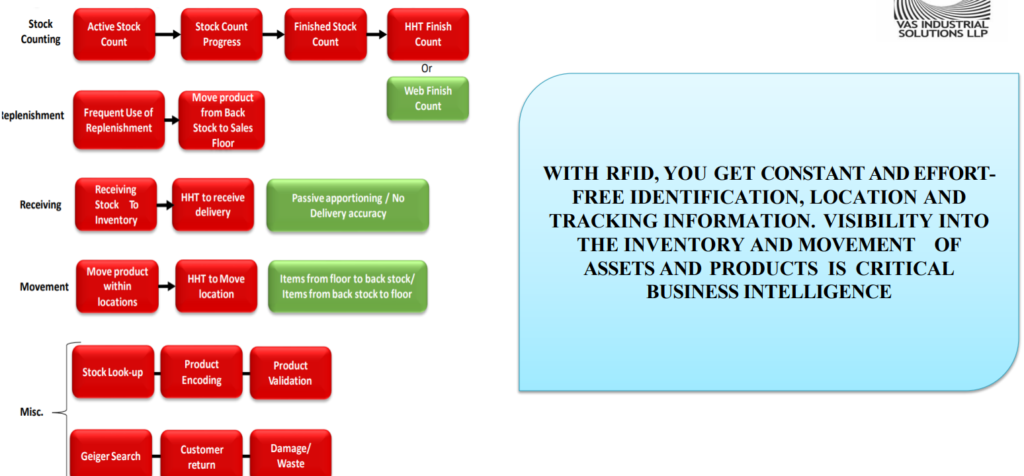

The Challenge: Better Visibility

- Saving time out of business processes has become a constant quest — the ability to get more done in less time will

ultimately reduce costs and strengthen the bottom line. - Virtually every business spends an excessive amount of time on the same initiative — obtaining the supply chain and

asset visibility required to manage the business better. - And no matter what industry you are in, chances are this effort is a tremendously time-consuming, manual and

error-prone activity that slows down the speed at which your business operates — and adds to the cost of doing

business. - RFID is helping organizations across industries all over the world address these issues by automating product visibility and asset management processes.

- With the power of RFID, your products and assets practically manage themselves, providing constant and effort-free identification, location, and tracking information.

- Your margins and profitability are under more pressure than ever before

Effortless Tracking Of Every Product Or Asset.

- Radio Frequency Identification (RFID) is a champion for providing real-time inventory, supply chain, and asset management

visibility, all with little or no human intervention. - The real-time visibility improves operations, and errors out of your everyday processes — from inventory, shipping, and receiving logistics to intelligent asset management.

- RFID is so versatile, you can find it at work in practically every industry, helping distribution centers track shipments as they

move in, out, and through the warehouse and perform more efficient cycle- counting and inventory operations and stock and

in the right locations. - Manufacturers ensure raw material availability and optimize sequencing processes

- This affordable, near-instant, and constant visibility turns into big business benefits. Fewer errors, increased automation, and a more efficient labor pool reduce costs and optimize business processes, allowing you to better serve more customers —

increasing sales and profitability. - Hundreds of hours previously spent managing items are drastically reduced, yet you know where every item is, all

the time — from inventory to returnable transport items (RTIs) to equipment, tools, and backup tapes.

Benefits In Manufacturing.

For manufacturers, success hinges on the speed and accuracy of their manufacturing operations. UHF RFID provides instant and accurate tracking of information at every step inside the manufacturing Plant, trimming wasted time and costs out of end-to-end manufacturing processes — from receipt of raw goods to RFID- enabling supply, sequencing, assembly, and shipping of final product. The net result is a leaner and more profitable manufacturing operation.

Applications

- End-to-end warehouse operations

- Quality assurance

- Line sequencing, raw material supply

- E-Kanban/replenishment

- Work-in-Process (WIP)/Just in time (JIT)

Benefits - Improve inventory accuracy — from raw to finished goods

- Improve product quality with increased automation of process and materials visibility

- Increase shipping and receiving accuracy

Benefits In Distribution And Warehousing.

- In the distribution industry, profitability is tightly tied to how fast and accurately inventory moves in, through and

out of the warehouse. - With UHF RFID, warehouse workers have the visibility they need to process thousands or hundreds of thousands of

items every day, as fast and accurately as possible.

Applications - Shipping and Receiving

- Put-away and picking

- Cross-docking

- Returnable Transport Item (RTI) management

- Inventory

Benefits - Achieve near-100 percent order and shipping accuracy

- Process orders up to 40 percent faster

- Improve workforce efficiency — reduce labor costs up to 30+ percent

- Improve inventory turns

- Automate advanced shipping notice (ASN) delivery and receipt

- Improve customer and trading partner satisfaction by delivering the right items on time, every time